Ceramic Injection Molding of Zirconia Keyboard Keys

2025-09-29

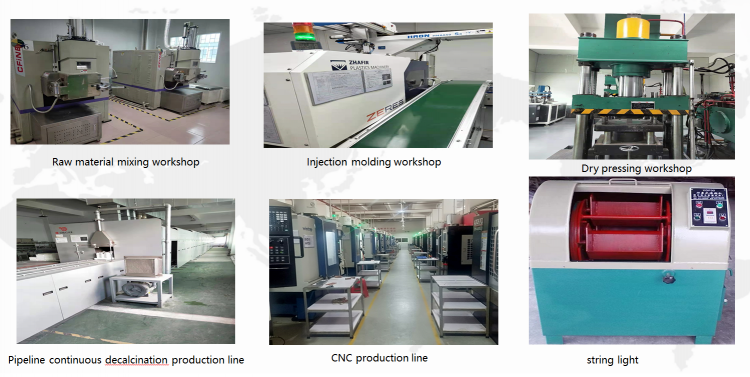

Ceramic Injection Molding of Zirconia Keyboard Keys Mixing: Zirconia powder is mixed with a thermoplastic binder to form a granulated feedstock. Molding: The feedstock is heated and injected und...