We are the largest manufacturer of zirconia ceramic coil atomizing core for vape (200 million pcs production) in Guangdong province 2021.

The core technology of electronic cigarette is the atomizing core of atomizing equipment.

The atomization core is equivalent to the CPU in the computer.

Its essence is the core component of the atomizer of the atomization device. Its function is to make the heating wire heat up through the battery power supply. After reaching a certain temperature, the e-liquid adsorbed on the ceramic begins to volatilize. The formation of smoke, so that people achieve the effect of inhaling smoke. The biggest difference from the atomizing core of traditional atomizing equipment is that its heating wire is made of clay and china clay, two kinds of clay with different properties. What are the advantages of the ceramic core of atomization equipment? The ceramic core of the atomization equipment is made by a new, drying, roasting and other technological process in the atomizer of the atomization equipment.

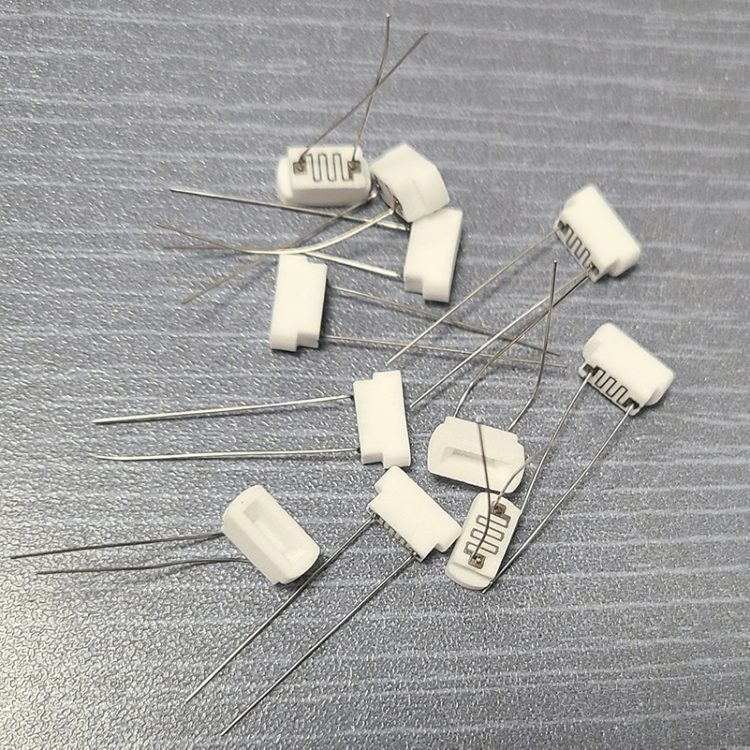

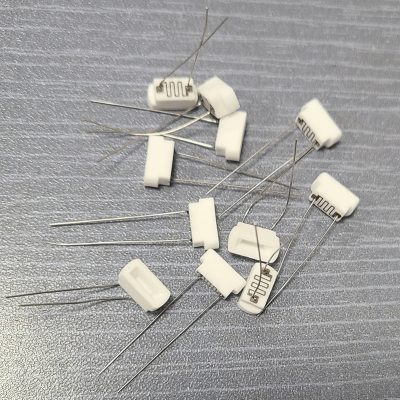

The ceramic coil is the standard configuration of the current high-quality atomizing equipment for small cigarettes. It adopts a porous ceramic structure. In addition to the atomizing core, there is also a type of ceramic oil guide tube, which is also made of porous ceramics.

At present, most of the e-liquid type atomization equipment adopts porous ceramic atomizing core. Porous ceramic is a new type of material, and porous ceramic is also called foam ceramic. Foam ceramics is named after a large number of non-closed channels distributed inside. It is a three-dimensional network skeleton structure. Because of its porosity, it is more conducive to the heat transfer of the e-liquid in the atomization and heating process of the atomization equipment and the better dispersion of the e-liquid. out, so this new type of porous ceramic material plays a very important role in atomization equipment.

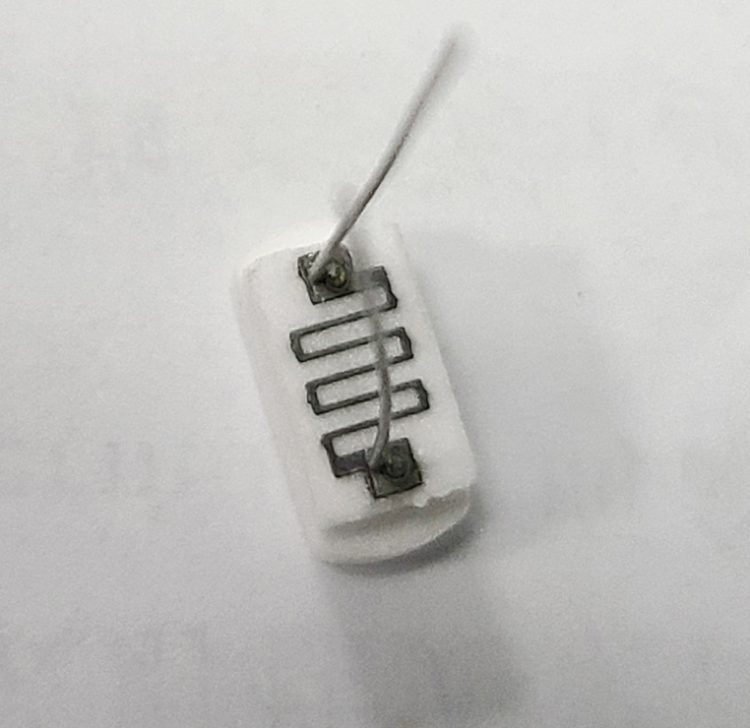

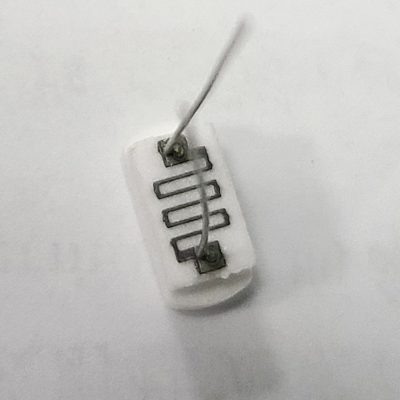

In the past three years, ceramic atomizing cores have been favored by the market due to their advantages of “no sticky smell and durability”, especially for pod pods, which mainly use ceramic atomizing cores. With the increasing market demand for ceramic cores, there are more and more companies supplying ceramic cores, but less than ten companies can really independently develop and produce atomizing cores, such as Maxwell, Huachengda, Juwei, Bodi, Zhuolineng, etc. While most of the ceramic cores on the market use the thick film printing process, Huachengda pioneered the world’s first inlay technology product - AX inlaid mesh ceramic core. Huachengda’s self-invented mosaic technology, inlaid with metal mesh on the surface of porous ceramics, not only increases the heating area, but also generates more uniform heat, which is stronger than the ceramic core of thick film printing process, and prolongs the service life by 1.6 times.